Making Data Matter

Making Data Matter / 2019 /

Christoph Bader, Dominik Kolb, James C. Weaver, Sunanda Sharma, Ahmed Hosny, João Costa and Neri Oxman

.

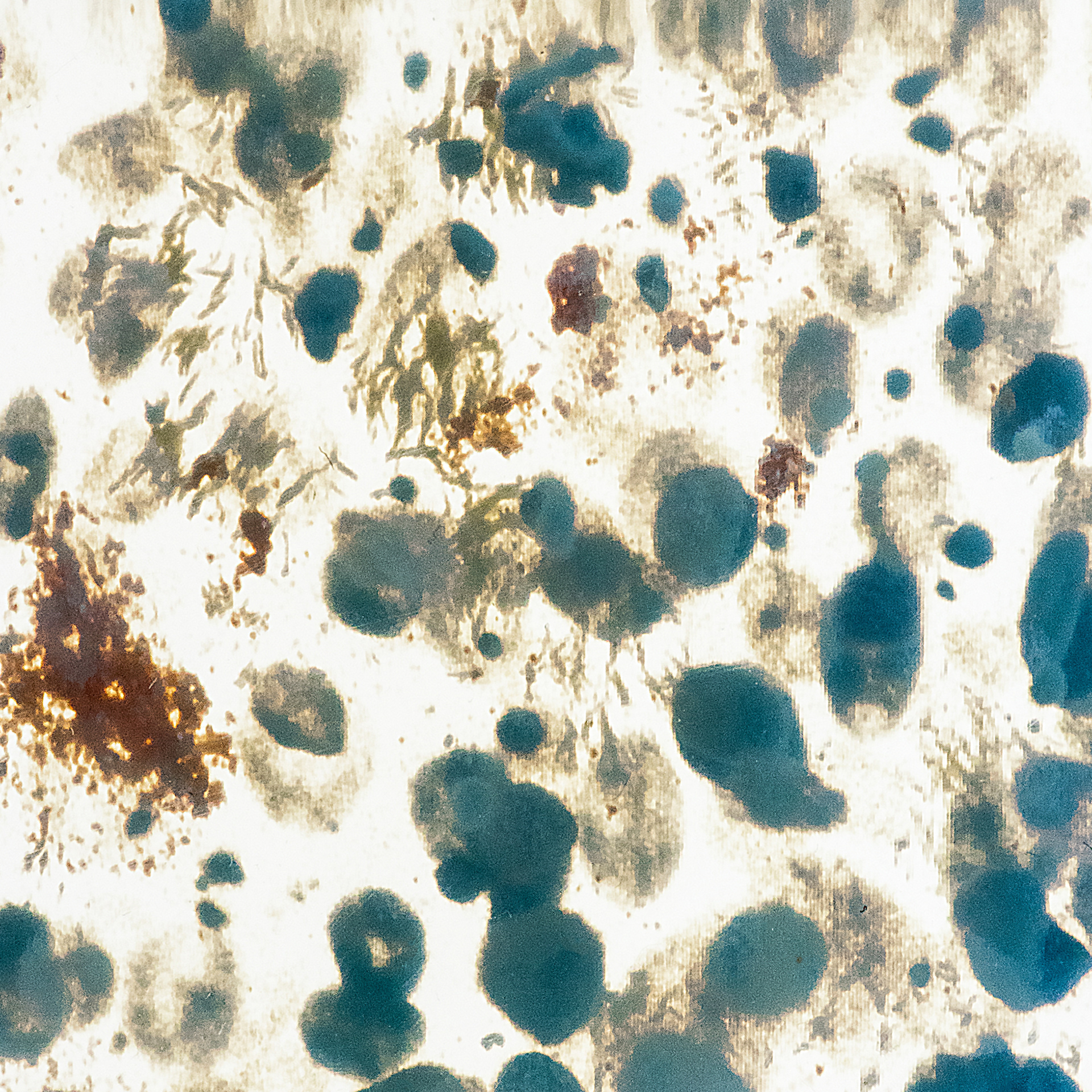

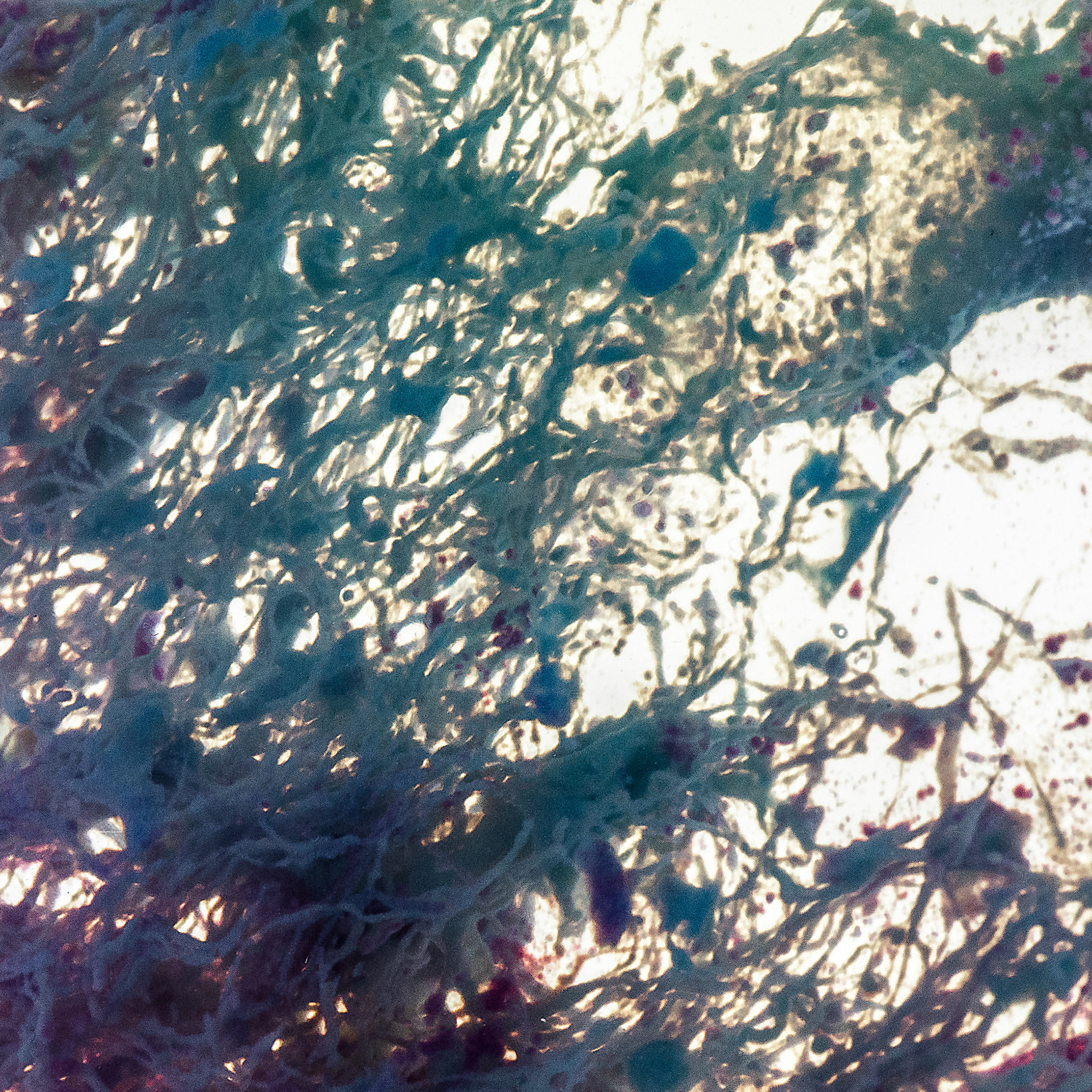

We present a multimaterial voxel-printing method that enables the physical visualization of data sets commonly associated with scientific imaging. Leveraging voxel-based control of multimaterial three-dimensional (3D) printing, our method enables additive manufacturing of discontinuous data types such as point cloud data, curve and graph data, image-based data, and volumetric data. By converting data sets into dithered material deposition descriptions, through modifications to rasterization processes, we demonstrate that data sets frequently visualized on screen can be converted into physical, materially heterogeneous objects. Our approach alleviates the need to postprocess data sets to boundary representations, preventing alteration of data and loss of information in the produced physicalizations. Therefore, it bridges the gap between digital information representation and physical material composition. We evaluate the visual characteristics and features of our method, assess its relevance and applicability in the production of physical visualizations, and detail the conversion of data sets for multimaterial 3D printing. We conclude with exemplary 3D-printed data sets produced by our method pointing toward potential applications across scales, disciplines, and problem domains.

While physical visualizations and representations of data are as old as prehistoric cave paintings, modern approaches still predominantly rely on the two-dimensional (2D) display of 3D data sets on planar computer screens. Scientific visualizations account for a wide range of such virtual information displays, including volumetric rendering of patient data obtained from magnetic resonance imaging (MRI) or point-based rendering of geospatial data obtained from photogrammetry methods. These visualizations map, process, and represent data and aim to allow a user to gather insights through perception and computer-aided interaction.

Although conventional screen-based media visualizations are known to be effective, it has been argued that physical manifestations of data sets can leverage active and spatial perception skills, enabling a more comprehensive understanding of presented information in an inherently intuitive manner. Immersive visualization through virtual and augmented reality displays aims to improve the shortcomings of 2D information displays but currently lacks the tangible interaction offered by physical information displays. Advancements in the accessibility and affordability of digital fabrication workflows, such as additive manufacturing, enable a “resurrection” of data in their physical manifestation. Consequently, the representation of data sets in a physical form through digital fabrication has emerged as a research area and practice. More broadly, the manifestation of data as a physical embodiment is often collected under the term “data physicalization” or “physical visualization”.

One of the earliest additive manufacturing methods introduced for the fabrication of scientific visualizations in physical form was powder-based binder jetting. This method has become particularly popular as it enables the digital fabrication of boundary representations with associated colored textures. While this approach allows the use of color as a parameter for the encoding of information on an object’s surface, the supplied data format must be given as a closed two manifold triangle mesh with associated texture or vertex attributes. Therefore, common representations used in scientific visualization must be converted to these boundary representations through geometry processing tasks, which may, in turn, result in partial loss or alteration of the data set at hand. Alternatively, crystal laser engraving provides a method to directly fabricate discontinuous data sets. In this process, a pulsed laser beam creates a large number of etched points captured within an optically transparent material. However, because this method works by introducing damage to a material, it is restricted to monochromatic visualizations and is limited in the spatial density of dots that can be achieved. Furthermore, the enclosing geometries are mostly constrained to simple forms such as rectangular blocks. Complex data sculptures—such as objects visualizing sound, landscapes, or graph-like structures—are often produced using selective laser sintering, where a laser fuses powder in a layer-by-layer fashion to form a solid object. Because of its ability to fabricate complex geometries without support scaffolds, it is suitable in cases in which intricate objects are required. However, given the very nature of the fabrication process, it does not enable the production of parts with varying translucency or color.

Furthermore, despite the availability and progression of 3D printing technology, fundamental 3D printing workflows have remained essentially unchanged for the past 30 years. These workflows are limited by the fact that shape specification is directly linked with material specification. This limitation is also reflected in the STL (stereolithography) file format, which was introduced three decades ago for the first stereolithographic 3D printers and is still considered the standard file format for additive manufacturing.

Here, and in contrast to the methods described above, we present an approach to physical data visualization through voxel printing using multimaterial 3D printing to improve the current data physicalization workflows. Multimaterial 3D printing with photopolymeric materials enables the simultaneous use of several different materials, and by using dedicated cyan, magenta, yellow, black, white, and transparent resins, full-color models with variable transparency can be created. The ability to create objects with and inside transparent material enables the physical visualization of compact n-manifolds (n ≤ 3) such as unconnected point cloud data, lines and curves, open surfaces, and volumetric data.

While multimaterial 3D printing is used in the sophisticated design processes of advanced products with complex geometries, it has only recently been used for the generation of data sculptures containing data-informed patterns. Our approach to physical data visualization through voxel printing using multimaterial 3D printing presented herein enables direct digital manufacturing of numerous data sets commonly found in scientific visualizations through rasterization, without the need to create intermediate representations for 3D printing. As a result, the method and its various applications point toward the elimination of the digital/physical divide, bridging digital on-screen data and their physical manifestations

Acknowledgements

We thank GETTYLAB and the Robert Wood Johnson Foundation for their generous support of our scientific research into programmable materials and living devices. We also thank N. Kaempfer (creative director of art, fashion, and design), B. Belocon, and G. Begun at Stratasys Ltd. for enabling the production of some of the models shown herein and their dedication and insights enabling the work in this paper. We thank B. Ripley, K. Benan, and S. Asano for providing data sets used in this study.

.